Pkg Solutions

Quality Glossary

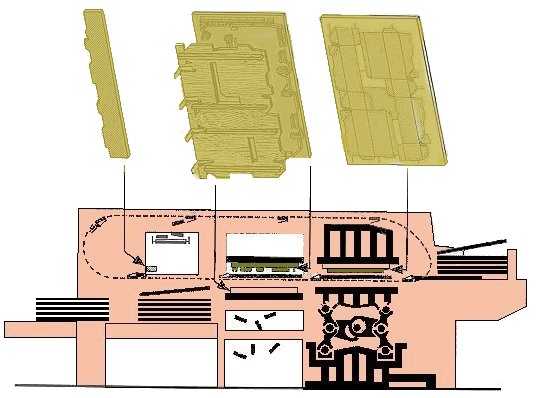

Flatbed Cutting and Creasing Press

An example of an Autoplaten

flatbed die-cutter is the popular Bobst SPO1600 machine, illustrated below.

The boards are stacked in the Suction feeder with suction

plate; the sheets are seized one by one and fed immediately into the platen

where they are pulled through the machine via gripper bars which hold

onto the lead edge of each board.

The first section Die-cuts the pack, using the cutting

cutting-die. The next section strips all of the waste with male and female

stripping cutting-dies. The carton then travels into the delivery station,

gathering in the delivery the blanks are stacked in bundles which are

counted by an electronically controlled pre-set magic-eye system. These

bundles are then carried to the take off on a conveyer system.

Some blanks my be run without front or back edge trim,

however this is not normally regarded as an suitable practice.

An automatic breaker can usually be used to separate

notched multi-out blanks, prior to them being tied and stacked on pallets.

Due to the many various control and safety devices,

as well as photo-electric cells that transmit their responses to a suspended

and movable control, the operator is able at a glance to establish that;

the machine is functioning properly.

All features of the machine make it easy

to set and operate and enable it to work at high stress and maximum speed,

although these factors depend largely on the type of job being run and

the grade of board being fed.