Pkg Solutions

Quality Glossary

ECT - Testing

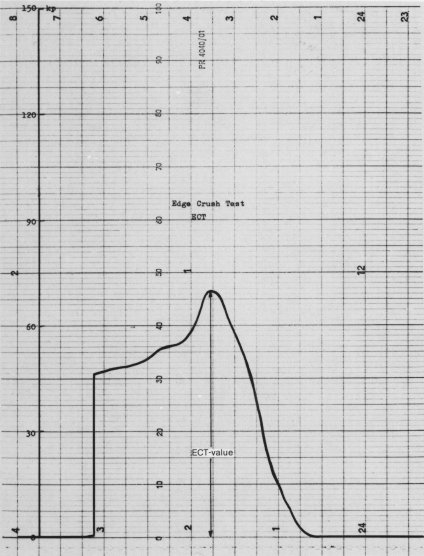

For the testing of ECT (Edge Crush Test), specimens

are cut with a length of 100 mm and the width of 25 mm from conditioned

board. ECT then is measured in a compression tester with the specimen

standing with the glue lines vertically.

10 individual specimens are crushed and the average

is calculated and reported in kN/m. 7 % variation is normal for a good

corrugated board. The American method with wax dipping the edges of the

test specimen or the Japanese method with "neck down" may somewhat

reduce the variation but even better is the calculation of ECT from the

crush resistance of the components liner and fluting.

|

|

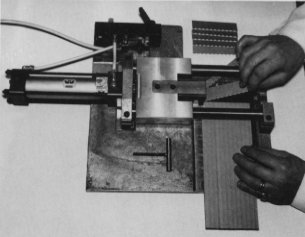

With a razor blade slitter

test sheets 100 mm wide are cut from the board, with the cuts being made

parallel to the flutes. The Billerud cutting table is a handy tool for

this purpose. |

|

|

From the test sheet, test

pieces 25 mm wide are cut perpendicular to the flutes. It is very important

that the cut edges are straight, clean and parallel and perpendicular

to the flutes. A special precision cutter has been developed by Billerud

and this device is now marketed by AB Lorentzen & Wettres Maskinaffdr,

Stockholm under the trade name "Billerud cutter". |

Scope And Application

This test is used to determine the compression rigidity

of corrugated board and solid fiberboard above 800 um. This property is

related to the prediction of a board's performance when used in cartons

or fiberboard cases.

|

|

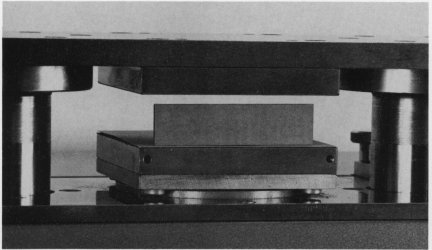

Principle

A test piece is subjected to an increasing force applied

in the direction of the shorter dimension of a sample strip in a compression

tester conforming to standard design

Test Piece Holder

The holder consists of two bare of rectangular cross

section which can be held together such that the full length and 19 mm

+/- 0.2 mm of the test piece is securely clamped in a vertical position.

Cutting Device

Ten strips must be cut with absolutely square edges.

Solid board test strips may be cut by guillotine.

Corrugated board strips are cut using the illustrated

cutter. |

|

|

Sampling

Samples and specimens to be selected according to intended

application of tent, i.e. as required for routine testing or in accordance

with BS 3430.

Preparation and Conditioning

of Test Pieces

Condition specimens in accordance with BS 3431 (Test

conditions 65% R.H and 20 degrees C). Cut sufficient test pieces for test

purposes. For normal needs board is only tested in the "across machine"

direction, i.e. grain running in the longer dimension of the strip. Tests

may be conducted in machine direction as required. Strips must be cut

cleanly and with parallel edges.

Test pieces should be cut:

100.0 +/- 0.1 mm X 25.0 +/- 0.1 mm

COMPRESSION TESTER SPEED: 10mm / Min

Procedure

Test in standard conditioning atmosphere. Place specimen

strip in the holder tighten sufficiently to ensure strip is vertical without

damaging the specimen. Operate the tester until the test piece collapses.

Record the maximum. force sustained by the test piece before collapse

to the nearest Newton. |

Report

1) For machine-direction and across machine-direction

separately, the mean of the test results to the nearest Newton together

with the range of results. Results should be reported in units of KN/M.

2) Any deviation from this standard method