Pkg Solutions

Quality Glossary

T.Q. Principles

The principles of T.Q. are a set of common sense beliefs that determine

the individuals actions in everyday life not just at work!

It is a fascinating effect of T.Q. that individuals do apply T.Q. to

their non work lives, particularly when affected by poor service in a

Restaurant or Hotel or Transport The reason for this is that the focus

and awareness of Quality is increased through the understanding and application

of T.Q. Principles and meanings.

PERCEPTION OF QUALITY

One at the biggest problems faced by a Company in implementing T.Q.

throughout the organization is the understanding of what is meant by the

term "Quality"

It is essential that there is only one definition of Quality which everyone

can understand and that makes sense. Unfortunately Quality means different

things to different people.

For example, the Media, advertisements, Marketing etc., portray Quality

as meaning "excellent", "luxurious", "expensive"

etc. all subjective terms. The trouble with this concept is that Quality

means pretty well anything you want it to!

In Business Quality is associated with "Quality Control" the

inspection of people's work in order to make sure it meets the Quality

Control Standards. This approach suggests to the People in an Organization,

that the only department responsible for Quality is the Quality Control

or Q.C. department.

These definitions, or to be more accurate, perceptions of what Quality

means to the people in an organization have to be changed.

It is essential that everyone in the Organization believes in one definition

or Quality and believes that Quality relates directly to them, as individuals,

and as members of a team.

This is a challenge We that has to be confronted head on by Management

It is no use taking the T.Q. implementation and calling it something else

In other the word Quality out in order to avoid confusion with "Quality

Control". I have been asked on occasion by Company Top Teams: I wish

we could call this T.Q. something different after all everyone thinks

Quality is about Quality Control, but what You are talking about affects

the whole Company it is to do with everyone."

"It Is to do with Everyone", that is precisely why It is necessary

to change the perception of what Quality means to the Organization. What

is there to be gained by keeping the old perceptions and meaning of Quality?.

the answer is, nothing at all and the sooner that Quality is re defined

to allow Everyone in the Organization to feel it relates to them, the

better.

Quality needs to be defined simply as "MEETING AGREED REQUIREMENTS".

Meeting Agreed Requirements between:

INDIVIDUALS

SECTIONS

DEPARTMENTS

DIVISIONS

COMPANIES

T.Q. is a tough discipline It is not an easy matter to define requirements

clearly, or to obtain agreement much less to achieve those agreed requirements.

It takes time to even get to 11rst base on occasions that is definition

of requirements, bit what we be avoided is half understood agreements.

What happens as the T.Q. Principles are spread throughout the Organization,

is that Individuals begin to use a common language it is a common language

for QUALITY. For example, it is common to hear the words: "My requirement

is" instead of:"I think I need".

Defining Quality clearly, simple and in a manner that enables everyone

to understand what it means is the FIRST REQUIREMENT (to use the language!)

of T.Q. implementation. The first principle of T.Q. is therefore:

QUALITY MEANS "MEETING AGREED REQUIREMENTS"

INTERNAL CUSTOMER CONCEPT

Having understood what Quality means it is necessary to consider the

Customer Supplier relationship. It is easy to understand when "the

Customer" is the Company buying your Product or Service. It is less

easy to understand the concept of the INTERNAL CUSTOMER.

It is a fact that each person whatever process he / she is responsible

for has a Customer and a Supplier. No one in an organization is exempt

to this fact, even though some people might wish to ignore it!

It follows from this straight forward fact, that each person is therefore

both a Customer and a Supplier and has to recognize this in order to ensure

the Process he / she is responsible for is completed to the Requirement.

The simplest way to understand this is to ask two simple questions for

every process that is completed.

1. WHO IS MY CUSTOMER? (Do I have Agreed Requirements?)

2 WHO IS MY SUPPLIER? (Do I have Agreed Requirements?)

This understanding of the chain link interdependency of people in organizations

is fundamental to achieving Quality Improvement. It is only a strong as

its weakest link and the reason that achieving the Business benefits such

an understanding delivers is so difficult, is that It has to be understood

and applied by EVERYONE. Achieving this understanding is the greatest

difficulty in implementing TOTAL QUALITY successfully and within a realistic

time scale.

BARRIERS TO UNDERSTANDING

What is the problem in understanding such a simple concept as the Internal

Customer - Supplier relationship?

The answer to this is ATTITUDE! For example the attitude of a Marketing

Manager when told that his customer is the Design Manager or the attitude

of a Design Engineer when told that his customer is a Production Shop

Floor Operator.

The barriers are "Perceived Status", Compartmentalization,

or sheer big headedness!

"Do you mean to say that Person is my Customer"?"

"Do you mean I have to speak to him!'

"Do you mean I have to ask him / her what he / she requires?"

The usual response is as follows, "Not likely I tell other people

what to do!"

This Status Conscious attitude is at the heart of the Western inability

to successfully implement the T.Q. Quality Improvement Process.

This conviction that Management and in many cases Qualified Engineers

"know it all and have nothing to learn" is the root cause that

will have the effect of destroying any T.Q. implementation process before

it has begun.

How can one person know and understand all the Processes managed by

all the people in the Department or Organization?

How can one person be expert in all those Processes and most importantly

of all: How can one person continuously improve all the processes in the

Organization at the same time!

The answer, of course, is that one person cannot, and that the person

running the process must be the expert whether it be a Hotel Receptionist

running the process at booking guests in, or the Secretary typing a letter,

or a Goods Inward Clerk booking in material from Suppliers, etc.

Once management recognize that they have people working for them who

should be experts in their job, the Management role is clearly understood

in terms of the Customer - Supplier relationship and to ensure that requirements

are agreed and managed through communication, teamwork and Management

Support.

The realization that the Manager has people working for him/ her who

are customers as well as suppliers is the key to good T.Q. management.

There is no room for the Status Conscious Manager who hides behind an

office door and therefore breaks the line of communication to his people.

How can there be a Customer - Supplier relationship where the Customers

aren't allowed to enter the shop!

Each Manager, each person needs to ask the question:

We do I need to do to ensure my customer can do his/ her job to the

Requirement Agreed?!

This question does not take account of Qualifications or status - only

the requirements of the people in the Company trying to do their jobs

property

CONTINUOUS IMPROVEMENT ATTITUDE

The definition of Quality:

Meeting Agreed Requirements using the Concept of the Customer/Supplier

Relationship is fundamental to the achievement of Business Requirements.

However, Business Requirements never stay constant Competition is always

there. Companies need to be constantly improving their Service to Customers,

developing new Products to capture or maintain Market Share. It is a tough

and ever changing environment to work in and it is getting tougher and

more changeable all the time.

It is essential that Companies recognize the importance of the Process

of Continuous Improvement in all areas and involving all people in the

organization.

It is hard enough to reach a situation where all people understand that

quality means Meeting Agreed Requirements using the Customer Supplier

Concept. However when those requirements have been met a new set of tougher

requirements have to be agreed!

Sometimes this is a tough fact to accept when a lot of hard work and

combined effort has gone into achieving a specific Requirement - which

may have been considered "impossible" at one time. It is tempting

to "bask in the success" and forget that a new set of requirements

need to be agreed!

This is the attitude of Continuous Improvement - not being satisfied

with meeting the requirement once, but improving all the time.

When this Continuous Improvement Attitude prevails in all the People

in an Organization, that organization is going to be, or already is World

Class.

ZERO DEFECTS

When Continuous Improvement is the attitude in an organization it is

logical that the standard required for everyone is Zero Defects. However

it is important to understand that Zero Defects needs to be qualified

by talking about:

"CONTINUOUS IMPROVEMENTS TOWARDS ZERO DEFECTS"

In other words, although Zero Defects is the only acceptable error rate,

it has to be achieved through a Process of Continuous Improvement It is

a mistake sometimes at the start of the T.Q. Process to ram "Zero

Defects" down people's throats It will likely be used by the cynics

to suggest that T.Q. is "not real world", "a waste of time",

"impossible" etc.

They will argue that Zero Defects is beyond their Process Capability,

this is an argument used very often by Engineers e.g. "I can't design

software with zero errors per million lines of code you don't understand

the Process capability".

The answer to this is to obtain agreement on the Requirement for the

Product in the Market place, which may not be Zero Defects! Then to ask

the Person 'When you have achieved this, are you going to - Continuously

Improve towards Zero Defects?"

In other words make sure you set and meet the Requirements and then

continually improve always changing the requirements towards zero defects.

It is useful with the cynics to test their attitude towards Zero Defects.

For example, as a customer they don't expect their pay check to ever be

wrong! No one would ever allow a nurse to drop a baby. These are Zero

Defects Requirements.

PLANNING FOR PREVENTION

The Process of Continuous Improvement requires an approach to situations,

all situations, that can be best called Preventative.

It is based on the belief that if something can go wrong then at some

stage it certainly will.

The requirement is to think through fully the activity or process to

be performed and ensure the necessary actions are taken to PREVENT things

going wrong.

At this stage many people will say: "I simply don't have the time

to spend thinking things through to that extent." This is one of

the hardest principles of Total Quality Management to actually "live",

because of the huge and conflicting demands on people's time.

There is enormous pressure to "fix" things that go wrong,

the FIX IT MENTALITY. It is rare that the root cause of a problem is identified

and action is taken to prevent the same problem occurring again. If you

think about it, this is why people don't have time to apply preventative

thinking and actions, it is a treadmill characterized by a "fire

fighting", reactive Management style. This approach needs to be changed

in order that Managers, in fact all the people, not just Managers create

more time to plan and prevent problems occurring in the first place. The

elimination of root cause problems once and for all is a key requirement

if the benefits of Total Quality Management are to be achieved.

T.Q. Management meetings and all action plans should be based on eliminating

root cause problems.

A key question to ask and to keep asking is this: "What are we

going to do differently to ensure this problem never occurs again?"

This question needs to be asked again and again until everyone fully

understands the need to take specific actions to ensure the elimination

of the root cause for ever.

The challenge is to recognize that FIXING problems is not enough and

that time and training is needed to change from fixing to the preventative

style

PROBLEM SOLVING FOR THE INDIVIDUAL

Training is required for 100% of people in the Organization to learn

the right approach to problem solving. This needs to be simple and effective

such that it can easily be applied to everyday problems. It is not sensible

to bombard people with "75 tools and techniques" of ranging

complexity; which is an approach sometimes adopted by companies attempting

to establish a Problem Solving capability in their people. The problem

with this approach is that so much time is spent in learning the individual

techniques that no time is left for understanding how to apply them!

The majority of problems can be solved with the technique described

in this course, simple, easy to use, and successful.

Before describing the appropriate technique, however, there is an absolute

requirement to understand the Problem Solving Cycle. This thinking, the

approach to Problem Solving which is required from 100% of people. It

is essential that this Problem Solving Cycle is fully understood before

training People in Tools and Techniques otherwise nobody will know when

to use which technique. The problem with many tools and techniques courses

is that, because the Problem Solving Cycle is not fully explained or understood,

people have great difficulty in understanding their application.

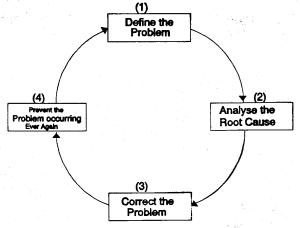

The Problem Solving Cycle is as follows, and has 4 steps

Four Step Problem Solving Cycle

STEP 1 - The

first step is to clearly define the problem to use the Japanese terminology

"What is the Fact". The temptation is to jump to conclusions

without ever really studying the problem in the first place.

STEP 2 - The second step is

to analyze the information and establish the root cause problem.

STEP 3 - The third step is to

solve the problem by applying a corrective action, which meets the immediate

requirement

STEP 4 - The fourth step is

to take the actions to ensure the problem can never occur again. This

is very often different to STEP 3 in actions as it may mean a change to

a Process method, or system. It may be the promise of new or additional

training, better communication between people. This is the key Prevention

step, this problem should never be allowed to happen again.

THE PROCESS OF CHANGE

To change from a traditional organization to a T.Q. one It Is necessary

to:

Change the way you look at competitive position

Develop top down processes that replace command

and control approaches. Effective communication of vision and values is

critical.

Increase the range of management styles, of teams,

or individuals

Bring in new systems.

Educate and train

Develop a continuous improvement initiative that

brings in results

Motivate and recognize.